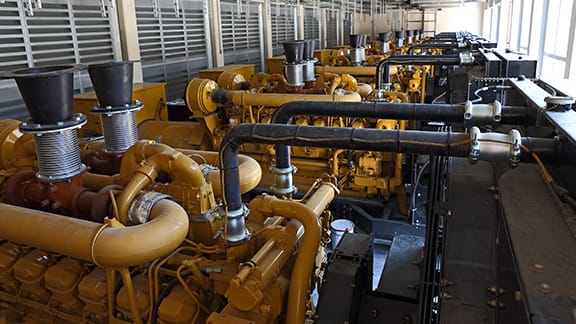

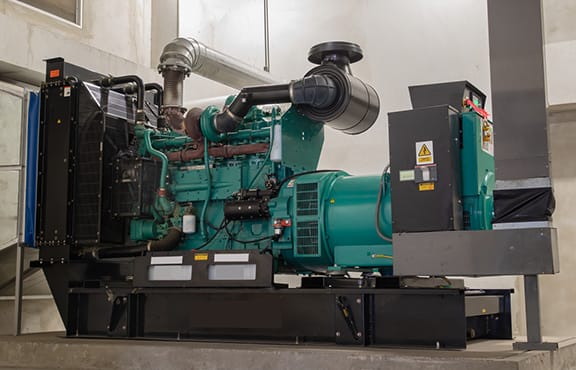

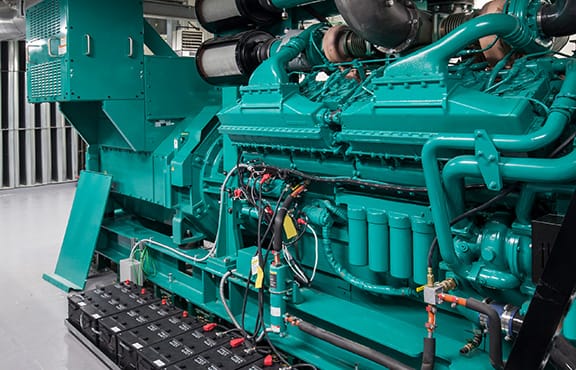

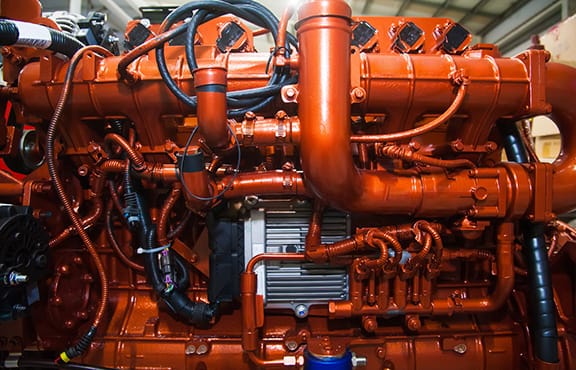

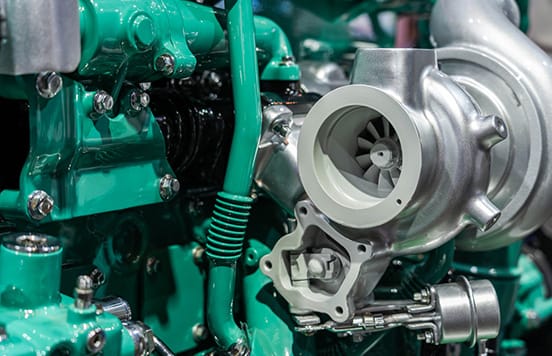

ECU Remapping Services For Industrial Equipment

Fine-tuning engine performance is often the most cost-effective way to increase output, boost productivity and reduce the running costs of heavy industrial equipment.

Our software engineers have the expertise, backed up by our extensive R&D program, to solve a whole range of industrial engine performance issues. We have field-tested and proven remaps available for many large diesel engines, but our experienced team can customise any remap for a specific application or use-case.